Chemicals Management

At Victoria’s Secret & Co., we’re focused on partnering with our vendors and other industry leaders to promote environmentally sensitive practices throughout each facet of our garment production, including attention to chemical management in wastewater.

VS&Co’s chemical management program, established 10 years ago, has two key goals: ensuring our products are safe and minimizing the environmental impact of manufacturing.

We adhere to all relevant laws and regulations where our products are manufactured and sold, including the requirements of the European Chemicals Agency (ECHA) such as Registration, Evaluation, Authorization and Restriction of Chemicals (REACH).

Further, we require our lingerie and apparel suppliers to adhere to several rigorous policies and standards governing chemical management, including a ZDHC Manufacturing Restricted Substance List (MRSL), which is a list of chemical substances, including detergents, dyes and finishing agents, banned from use in textile operations.

We actively verify MRSL conformance of the chemicals from wet-processing suppliers (e.g., dyeing mills and laundries) who produce more than 90 percent of our materials (based on material value). All of the raw materials used in our lingerie and apparel products must be certified to Oeko-Tex® Standard 100 or tested to VS&Co’s Restricted Substances List (RSL) by a third-party laboratory to ensure substances used in making our products meet its requirements.

More specifically, we have built a chemical management program aimed at eliminating the discharge of the following 14 priority chemical categories in conjunction with the manufacturing of our lingerie and apparel products:

| Chemical | Function |

|---|---|

| AP & APEOs | Detergents, wetting agents, emulsifiers, softeners |

| Banned Dyes (azo, disperse, carcinogenic or equivalent concern) | Dyestuffs, pigment prints |

| Brominated and chlorinated flame retardants | Sleepwear |

| Halogenated solvents (TCE) | Paint, spot removers, metal cleaners |

| Chlorobenzenes | Solvents, dyestuffs, insecticides |

| Chlorophenols | Insect control, fungicides |

| Glycols | Softeners, anti-static agents |

| Heavy metals (cadmium, lead, mercury, chromium VI) | Dyestuffs, leather tanning, paints, alloys, pesticides |

| Organotin compounds | Catalysts, inks, paints |

| Perfluorinated chemicals* | Water, oil and stain repellents |

| Phthalates | Flexible plastic components, e.g. PVC, print pastes |

| Polycyclic aromatic hydrocarbons (PAHs) | Rubber/plastic components, lubricants |

| Short-chain chlorinated paraffins | Flame retardants, leather greasing |

| Volatile Organic Compounds (VOCs) | Adhesives, textile finishes |

*PFOA and PFOS banned by Victoria’s Secret & Co. as a part of L Brands since 2013 and became a standalone company as of August 2021.

**The full list of priority chemical categories can be found in the MRSL.

We also require our lingerie and apparel suppliers to adhere to our proprietary Global Apparel Chemical Policy, a guidance document for suppliers that outlines our expectations around the use of chemicals. For example, the document requires suppliers to keep an inventory of chemicals used, to treat wastewater prior to discharge and to possess required permits.

The success of our chemical management program relies on close collaboration with our suppliers to ensure chemical purchases, manufacturing practices and the quality of water discharge are aligned with our commitment to eliminate priority substances. Some of the ways we engage with our suppliers include:

- Sourcing agreements with suppliers outlining their accountability in the ban and removal of the 14 priority chemical groups

- Annual training on chemical management best practices

- Review of chemical inventories and supporting documentation

- In-person and virtual audits of suppliers’ chemical management and manufacturing practices and subsequent follow-up on corrective action plans

- Regular testing of on-site water and waste streams

Our chemical management audits include review of:

- Supplier’s chemical storage and handling practices

- Environmental permits, personal protective equipment and safety policies

- Management’s commitment to achieving zero discharge of the priority chemicals

- Presence of technical staff person(s) with the required competencies to operationalize improved chemical management

We continue to work closely with our lingerie and apparel suppliers to regularly assess compliance. Through our Product Stewardship Audit, we track compliance with our chemical policies, measure and reward performance through our Chemical Management Scorecard and address non-conformance with a corrective action plan or suspension from our supplier list, if needed. We provide training to partners on chemical management best practices and have secured agreements with more than 90 percent of our suppliers to gain their participation to ban and remove priority chemical groups from their supply chains. In 2021, we set a target for core lingerie and apparel suppliers to use 100 percent certified MRSL-conformant chemicals in products by 2030. To date, more than 90 percent of suppliers’ chemical formulations are certified with ZDHC MRSL conformance level 1 or above.

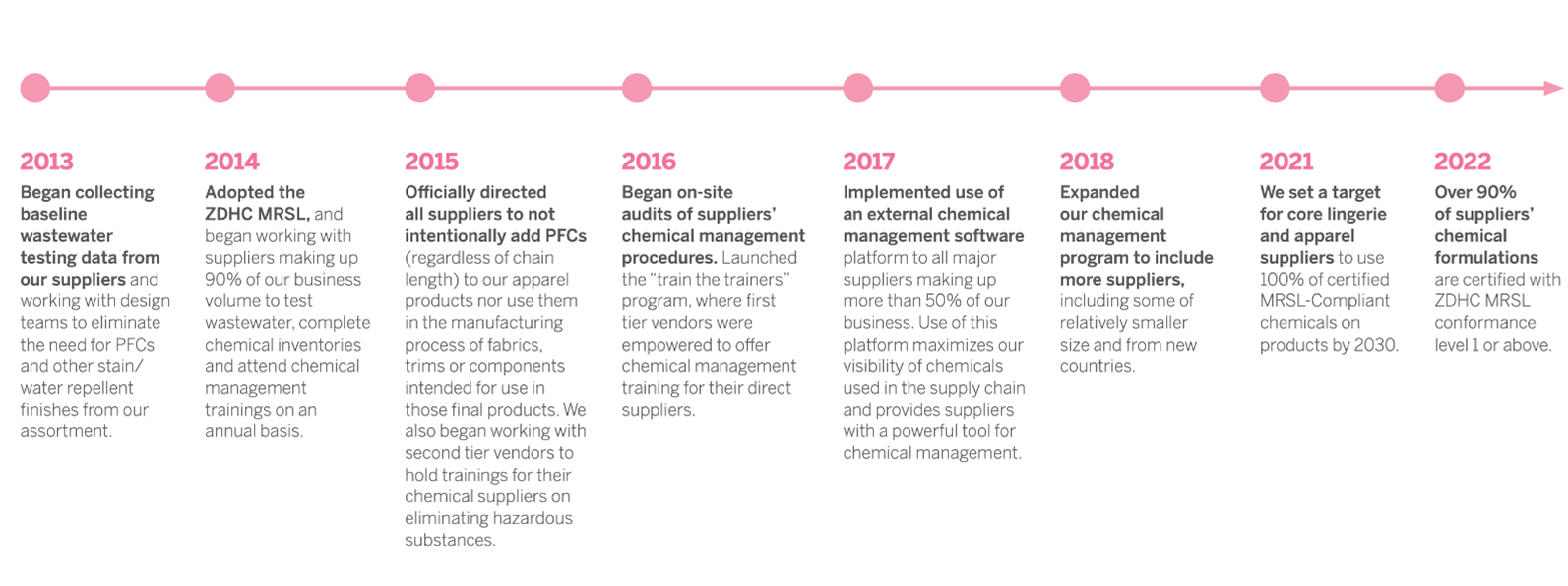

MILESTONES IN OUR CHECIMAL MANAGEMENT PROGRAM

The following timeline outlines when each of these engagement activities was implemented, as well as other important milestones on our journey to ensure environmentally sensitive manufacturing:

Wastewater Testing In Product Manufacturing

Victoria’s Secret & Co. sees its wastewater testing program as a key element in tracking progress towards the goal of eliminating targeted chemicals.

We conduct regular testing on our lingerie and apparel suppliers’ wastewater to ensure progress toward our goal of eliminating targeted chemicals. Since 2014, we have collected wastewater testing data from our suppliers and worked with them to eliminate hazardous chemicals from their discharge.

In 2022, we collected more than 90 percent of our wet-processing suppliers’ wastewater testing data and worked with them to eliminate hazardous chemicals from their discharge.

We require our wet-processing suppliers to have their wastewater tested annually by a ZDHC-approved third-party lab. Among the facilities tested in 2022, 91 percent had passing results for MRSL levels, 92 percent for heavy metals and 94 percent for other conventional parameters.

When a chemical listed on our MRSL is found in above-acceptable limits in treated or untreated water, we work with the supplier to identify the source of that chemical and to find a compliant alternative. For example, if we determine that the chemical is generated during production, we work with the supplier to identify the necessary adjustments to the production process to prevent the generation of this chemical. We then require them to have their wastewater retested to verify the restricted chemical is no longer present.

Public Disclosure

We require all our China facilities to report their water testing data on the Institute of Public & Environmental Affairs (IPE) or ZDHC Detox Live platforms.

ENVIRNMENTAL MANGEMENT IN THE SUPPLY CHAIN

As Sustainable Apparel Coalition (SAC) members, we utilize data from SAC’s Higg Facilities Environment Module (FEM), an assessment tool that standardizes how our manufacturing partners measure, evaluate and report on the environmental performance of our facilities year over year.

This FEM assessment includes:

- Environmental management systems

- Energy use and emissions

- Water Use

- Wastewater

- Chemical management