Accountability & Remediation

Victoria’s Secret & Co. maintains policies and procedures for associates and suppliers that govern the consequences of noncompliance with Victoria’s Secret & Co.’s sourcing and labor standards.

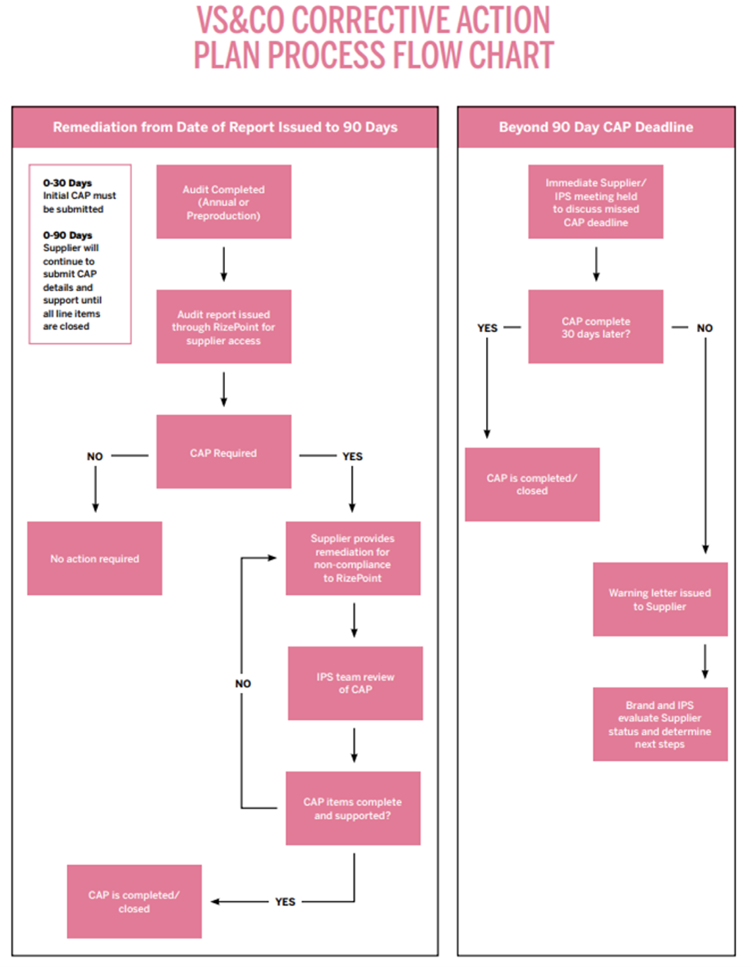

If we find a supplier or factory is not in compliance with our Supplier Code of Conduct or supply chain standards, we will partner with them in an attempt to bring them into compliance. Victoria’s Secret & Co. has a robust remediation system where a corrective action plan (CAP) is automatically created for all non-compliance findings and suppliers are automatically notified when they need to complete a CAP. It is the supplier’s responsibility to submit all CAPs within 30 days. All corrective actions are expected to be completed within 90 days of receiving notification. All corrective action correspondence and support evidence is thoroughly documented in the system.

During fiscal 2019, more than 18,937 labor standards and workplace conditions audit findings were evaluated across our supply chain through our standard auditing process, and approximately 9.5 percent of those findings required corrective action. Less than one percent of those were considered major violations, the majority of which concerned unauthorized use of subcontracting. The overwhelming majority of violations were successfully remediated by the factories in partnership with IPS, and those that were not resulted in the factory being removed from the Victoria’s Secret & Co. approved factory list.

In 2020, more than 9,043 labor standards and workplace conditions audit findings were evaluated across our supply chain through our standard auditing process, and approximately 10 percent of those findings required corrective action. Less than one percent of those were considered major violations. The labor standards and workplace conditions audit findings were successfully remediated by the factories in partnership with IPS, and those that were not, resulted in the factory being removed from the Victoria’s Secret & Co. approved factory list.

In 2021, more than 12,226 labor standards and workplace conditions audit findings were evaluated across our supply chain through our standard auditing process, and approximately 10.7 percent of those findings required corrective action. Less than one percent of those were considered major violations. The labor standards and workplace conditions audit findings were successfully remediated by the factories in partnership with IPS, and those that were not, resulted in the factory being removed from the Victoria’s Secret & Co. approved factory list.

For major violations, IPS issues a warning letter and, in most cases, it includes a financial penalty. We provide the supplier with the option of waiving the penalty and continuing to work with us but only if they invest the money into building a robust and sustainable compliance program. If the factory agrees, we provide access to a third-party labor standards consultant who works in concert with the factory to identify the root cause of an issue and helps the factory build up their compliance program and management systems to ensure issues do not reoccur.

We have a dedicated corrective action management team that reviews CAP submissions daily. Once evidence has been provided to support full compliance or continuous improvement towards full compliance can be demonstrated, CAP submissions are approved.

If a factory does not make improvements in a timely manner, we have an escalation process in place which includes a warning letter to the supplier, reduction of business or ultimately loss of business. Victoria’s Secret & Co. will not work with suppliers and factories that are unwilling or unable to work with us to achieve our compliance standards. The company also has a more accelerated escalation process to be used if a case of forced labor is suspected or identified so action can be taken immediately.

In many cases, IPS conducts unannounced follow-up visits to the factories to ensure the supplier has implemented all new procedures and processes accordingly.

The company also has a more accelerated escalation process to be used if a case of forced labor is suspected or identified so action can be taken immediately.

In 2020, we identified two cases where forced labor indicators, as identified by the International Labour Organization (ILO), were identified in our supply chain. In both cases, the issue was immediately escalated to IPS and Victoria’s Secret & Co. leadership. An urgent meeting was scheduled with the respective supplier and the factory to immediately stop the practices observed as forced labor indicators.

Example 1: In November 2020, a third-party Labor Standards audit arranged by IPS was conducted at a factory in Thailand. During the audit, it was noted that workers were required to present a gate pass signed and approved by human resources or a supervisor before leaving the facility premises during lunch hours. IPS had call with the supplier, and they committed to immediately stop the practice, revise the procedure and conduct meetings with workers about the policy change.

Example 2: In November 2020, a third-party Labor Standards audit arranged by IPS was conducted at a factory in the Philippines. During the audit, it was noted that the factory had a practice of requiring a signed approval to restrict workers’ movement and workers could not refuse overtime. IPS had a call with the supplier, and the supplier advised that the factory had immediately abandoned the practice on the day of the audit and made an announcement to workers about the policy change and that overtime would be on voluntary basis in accordance with ILO standards.

Unannounced follow-up audits were conducted in 2021, and both facilities provided evidence of the policy changes. The audits were conducted in March 2021 for the facility in Thailand and April 2021 for the facility in the Philippines.